Subsea Needle Valves

High Pressure, High Temperature Needle Valves

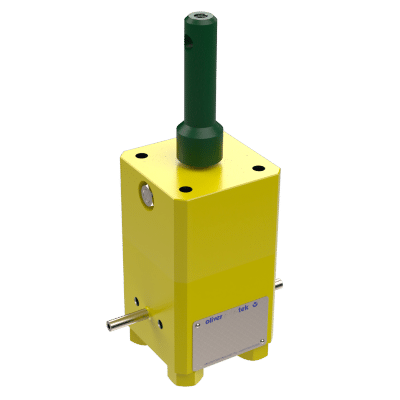

Oliver Valvetek Limited manufactures a range of small bore block or panel mounted subsea High-Pressure High Temperature (HPHT) needle valves with a bore size of 0.30” [7.6mm] bore.

HPHT needle valves have an operating pressure rating up to 20,000psi [1380 bar] and an operating temperature range of -29°C to +204°C (-20°F to +400°F). Qualified water depth rating of 10,000ft [3050m].

Oliver Valvetek manufactures specialist High-Pressure High Temperature (HPHT) Needle Valves for subsea use. Subsea HPHT Needle Valves are commonly used to provide a metal to metal seating isolation solution without resorting to the more complex and expensive gate valves. The valves are typically used on Christmas trees to isolate downhole safety valve lines and gasket test lines.

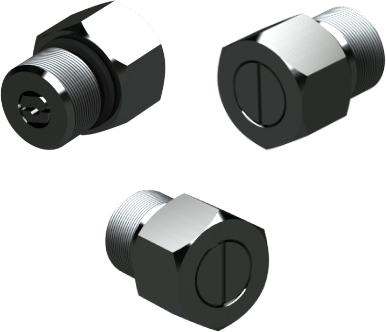

Oliver Valvetek this range of HPHT needle valves in bodies with either flanged, threaded and welded end connections to suit all applications. Valves can be configured with a choice of recepticles or stem adapters for connection to extension rods and stand alone ROV receptacles.

Qualification Tested has been completed in accordance with API 6A 20th edition appendix F and API 17D 2nd edition.

Product Information

-

Product features

Material selection – The HPHT needle valve materials of construction have been selected for this demanding application based on extensive Research and Development (R&D) testing and evaluation. Oliver Valvetek uses either UNS N06625, UNS N07725, UNSN09925 or UNS N07718 in our HPHT valve construction.

Operator – The needle valves can be supplied with a number of different operators, including different shaped adaptors for connection to extension rods for ROV operation or intervention.

Operating Threads – The range of subsea HPHT needle valves is a medium torque partial turn design.

Anti-Blowout Spindle – Each needle valve size has a spindle designed for maximum torsional (Torque to Damage) strength and has a back seat to provide an anti-blowout safety feature.

Environmental Seals – All needle valves have seals to prevent the ingress of seawater. These have been tested to water depths equivalent to 10,000 feet (3050m).

Body seals – Body to bonnet sealing is by using metal to metal gasket.

Gland Seals – The gland seal within each needle valve has been designed with a spring energised lower seal to prove dynamic adjustment of the packing gland seal in response to pressure changes. This feature ensures leak-free spindle sealing with no requirement for adjustment.

Non-Rotating Tip – The HPHT needle valve design has a non-rotating, self-centring, anti-galling spindle tip, which gives a positive bubble-tight shut-off.

Traceability of Materials – All the components within an Oliver subsea needle valve have material traceability. The needle valve body, tip, spindle, seal housing are manufactured as standard to API 6A PSL3. The complete needle valves are individually serialised and are provided with material and pressure test certificates to BS EN 10204 3.1 certifications. Optional EN 10204 with the intent of a 3.2 type certification option is also readily available (EN 10204 3.2 true mill witnessed shall be assessed for availability upon request).

Product Enquiry

If you would like more information regarding our needle valves, please fill out the form below, or contact us directly on +44 (0) 1565 632 636 or sales@valves.co.uk.