High Temperature Pipeline Valves

High Temperature Pipeline Valves

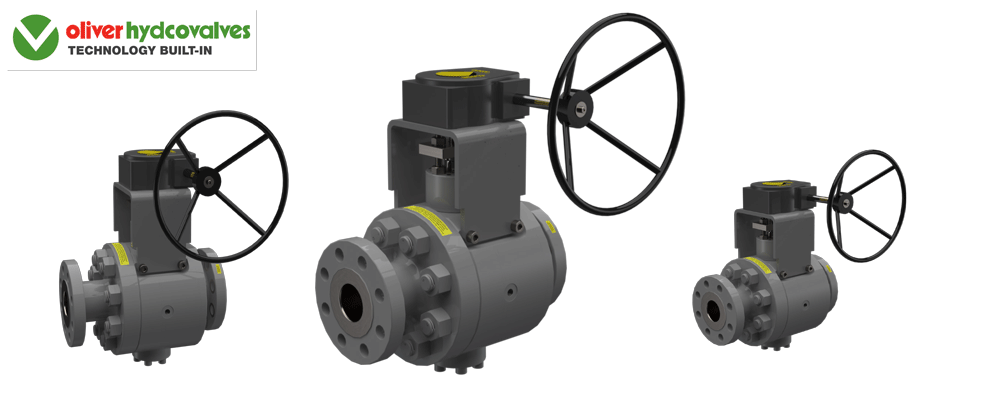

Our High Temperature ball valves are specifically designed for high temperature applications where soft seated valves are no longer suitable, typically for process temperatures higher than 200 degC / 392 degF.

Valve designs utilise qualified and field proven metal-to-metal seating, with carefully selected low permeable coatings that provide zero leakage performance. In addition, we have a range of high temperature sealing materials available for temperature ratings up to 500 degC and ultra-low emission applications.

Valve designs utilise qualified and field proven metal-to-metal seating, with carefully selected low permeable coatings that provide zero leakage performance. In addition, we have a range of high temperature sealing materials available for temperature ratings up to 500 degC and ultra-low emission applications.

Everything You Need for High Temperature Applications

Our robust trunnion design ensures low operating torques with ISO mounting pad suitable for gear operation or actuator mounting. Custom body and trim materials are available based on the process application and project requirements.

-

Pipeline Valve Design (Options)

- Double Block & Bleed – API 6D

- Single Isolate

- Single Isolate with DPE Seats

Seat Material

- Metal-to-metal Seating with Low Permeable Coatings

- Range of Sealing Materials Available for High Temperature and Ultra-low Emission Applications

Pressure Class

- ASME Class 150 – 2500

Temperature Range

- -50℃ up to +500℃

End Connections

- Flanged

- Butt Weld

- Hub

Bore Size Range

- 1″ to 20″ (inch) – DN25 to DN500

Operation (Options)

- Manual Operation

- Actuated Operation – Electric / Pneumatic / Hydraulic

Certified UK Valve Manufacturer

Ask any question

Oliver Twinsafe has been manufacturing customised valve solutions for the Oil, Gas, LNG, Petro-chemical, Nuclear, and Mining industries since 1979. If you don’t see the required valve specification listed here, please ask a member of our team.

-

Design Features

- Proven high temperature sealing technology for temperatures beyond 300ºC

- Low fugitive emission packing available

- Bi-directional sealing

- Forged 1 piece compact body, 2 piece or 3 piece body designs

- High integrity carbide coating of ball and seats

- Single Isolate, DIB or DBB designs available

- Suitable and proven for high-cycle operations (in house testing over 400 cycles)

- Specially selected low friction, high temperature bearings allowing high number of cycles

- Anti-static device

- Anti-Blow out stem

- Self-relieving seats

- O ring and Lip Seal seals available

- Weld overlay of full through bore or sealing areas available

- Manual or actuated operation (electric/pneumatic/hydraulic)

Qualification & Testing

- Firesafe Qualification Testing To ISO 10497, API 6FA And API 607

- Fugitive Emission Testing To ISO 15848

- Pressure Equipment Directive 2014/68/EU

- API 6A PR2 Annex F Qualification Testing – Independently Witnessed

Most Common Applications

- Downstream Refining

- Chemical Processing

- Steam Injection

-

(Download PDF) – Oliver Hydcovalves Brochure

-

NEW GENERATION VALVE TECHNOLOGY by Oliver Hydcovalves

Oliver Hydcovalves is an industry-leading company that harnesses over forty years of technology, development and expertise. Designing and manufacturing precision valves for hydrogen and carbon capture applications. Hydcovalves is committed to delivering valve solutions as part of the global ambition to reduce carbon emissions.

- Dedicated UK Research & Development Centre

- Engineering Partnership programmes, collaboration with suppliers

- Work with key supplier partner DuPont for best-in-class materials

- Engineering graduates work alongside experienced engineers on new valve designs

- Complete in-house testing capabilties that mimic real-world application

-

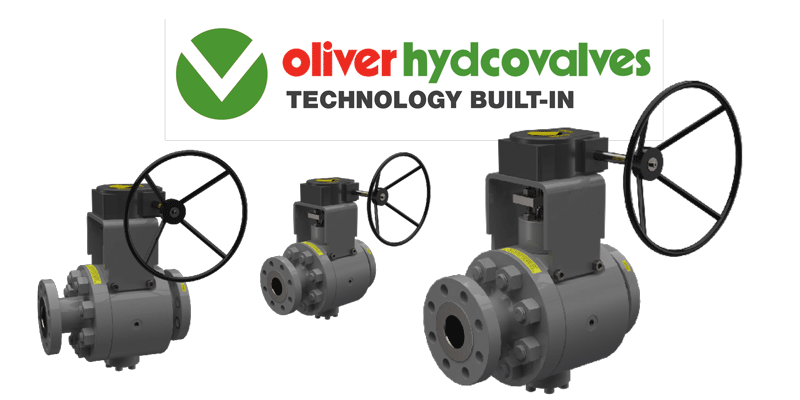

Pipeline Valve Design (Options)

- Double Block & Bleed – API 6D / API 6A

- Single Isolate

- Single Isolate with DPE Seats

Seat Material

- Metal-to-metal Seating with Low Permeable Coatings

- Range of Sealing Materials Available for High Temperature and Ultra-low Emission Applications

Pressure Class

- ASME Class 150 – 2500 / API 6A 3000, 5000, 10,000

Temperature Range

- -50℃ up to +500℃

End Connections

- Flanged

- Butt Weld

- Hub

Bore Size Range

- 1″ to 20″ (inch) – DN25 to DN500

Operation (Options)

- Manual Operation

- Actuated Operation – Electric / Pneumatic / Hydraulic

Certified UK Valve Manufacturer

Ask any question

Oliver Twinsafe has been manufacturing customised valve solutions for the Oil, Gas, LNG, Petro-chemical, Nuclear, and Mining industries since 1979. If you don’t see the required valve specification listed here, please ask a member of our team.

-

Design Features

- Proven high temperature sealing technology for temperatures beyond 300ºC

- Low fugitive emission packing available

- Bi-directional sealing

- Forged 1 piece compact body, 2 piece or 3 piece body designs

- High integrity carbide coating of ball and seats

- Single Isolate, DIB or DBB designs available

- Suitable and proven for high-cycle operations (in house testing over 400 cycles)

- Specially selected low friction, high temperature bearings allowing high number of cycles

- Anti-static device

- Anti-Blow out stem

- Self-relieving seats

- O ring and Lip Seal seals available

- Weld overlay of full through bore or sealing areas available

- Manual or actuated operation (electric/pneumatic/hydraulic)

Qualification & Testing

- Firesafe Qualification Testing To ISO 10497, API 6FA And API 607

- Fugitive Emission Testing To ISO 15848

- Pressure Equipment Directive 2014/68/EU

- API 6A PR2 Annex F Qualification Testing – Independently Witnessed

Most Common Applications

- Downstream Refining

- Chemical Processing

- Steam Injection

-

(Download PDF) – Oliver Hydcovalves Brochure

-

NEW GENERATION VALVE TECHNOLOGY by Oliver Hydcovalves

Oliver Hydcovalves is an industry-leading company that harnesses over forty years of technology, development and expertise. Designing and manufacturing precision valves for hydrogen and carbon capture applications. Hydcovalves is committed to delivering valve solutions as part of the global ambition to reduce carbon emissions.

- Dedicated UK Research & Development Centre

- Engineering Partnership programmes, collaboration with suppliers

- Work with key supplier partner DuPont for best-in-class materials

- Engineering graduates work alongside experienced engineers on new valve designs

- Complete in-house testing capabilties that mimic real-world application

Explore More Pipeline Valves in our Range

Contact Us. Our dedicated projects team and technical sales engineers can help answer your questions about High Temperature applications, and calculate the best pipeline valve solution for you.

Dedicated Projects Team

Our highly experienced projects team are dedicated to handling large-scale projects around the world. Often, projects are technically challenging and have complex material requirements and configurations that need to work for various applications including Hydrogen. Find out more, contact our team today.

Richard Featherstone, Sales Manager

Dedicated Projects Team

Our highly experienced projects team are dedicated to handling large-scale projects around the world. Often, projects are technically challenging and have complex material requirements and configurations that need to work for various applications including Hydrogen. Find out more, contact our team today.

Richard Featherstone, Sales Manager

Explore More Valves

Contact Us. Our dedicated projects team and technical sales engineers can help answer your questions about High Temperature applications, and calculate the best pipeline valve solution for you.

Our Working Partners & Customers