Oliver Valvetek’s unique approach to Subsea valve design and manufacturing is exemplary and world-leading. Engineering teams often take-on, sometimes, very complex and difficult to manufacture valve concepts and specifications required by customers, and to see them on the production line is truly remarkable.

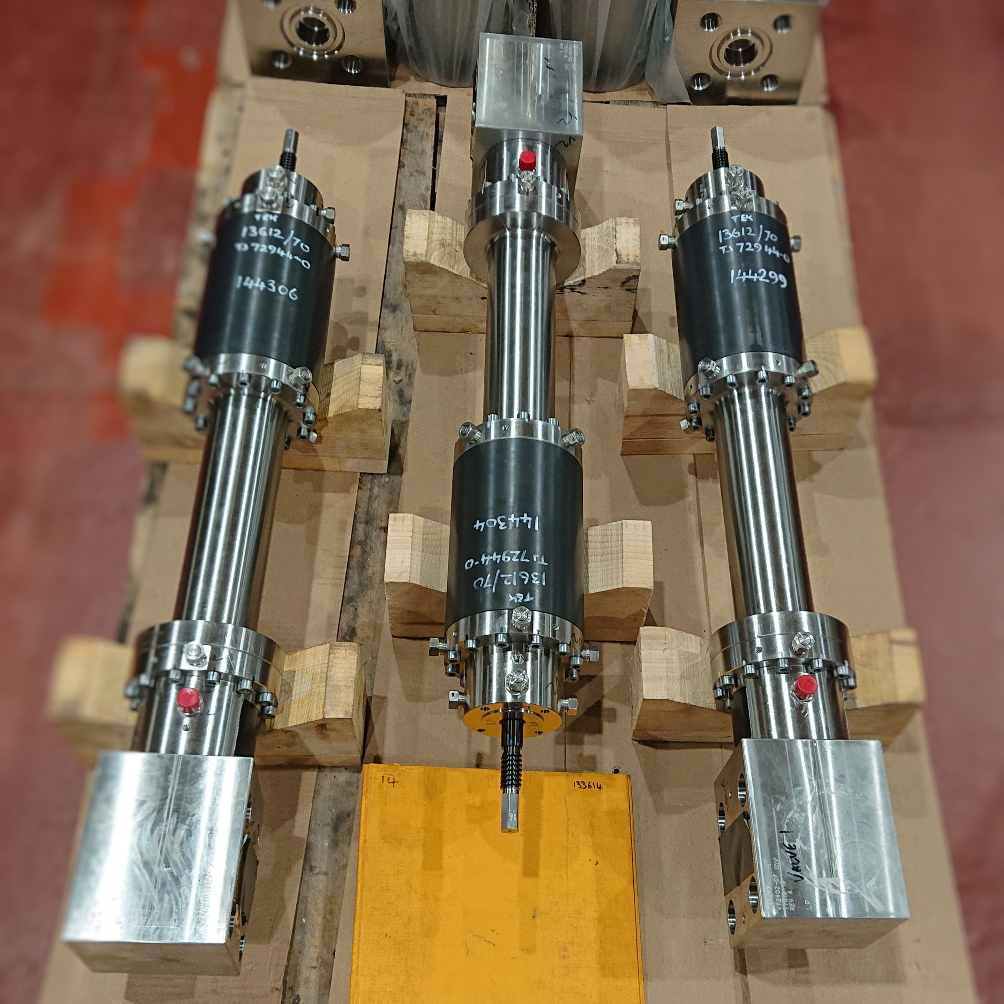

One recent example is a Subsea Gate Valve that was designed with the Actuator on an extension piece, and used in operation on a Total Moho Infill Subsea Project. This hybrid design allowed the valve to be fully covered by Christmas Tree insulation with the actuator on the outside of the insulation process.

For more information on Subsea valves, contact Oliver Valvetek on +44 (0)1565 632 636 or email sales@valves.co.uk | www.valves.co.uk