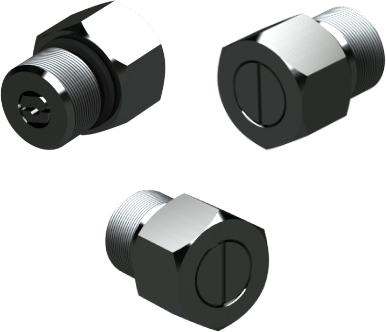

Subsea Ball Valves

Floating Type Ball Valve

Oliver Valvetek manufactures a range of small bore subsea floating ball valves, from 0.55″ [14mm] bore to 0.787″ [20mm] bore. These ball valves typically have an operating pressure rating up to 10,000psi [1034bar]. These valves have an operating temperature range of 0F[-18C] to +250F[+121C] and typical water depth rating of 10,000ft [3050m].

Subsea Ball Valves provide the user with a soft seating quarter-turn isolation solution for many different applications. The inline flow path of ball valves minimises flow losses, important on extended hydraulic control lines. They are commonly used to isolate hydraulic and chemical fluids associated with subsea oil and gas production systems.

Floating Ball valves are typically manually operated and due to the working pressures of the valves will typically have low operational torques but high torques to damage. The added benefit of these products is should the valve be over-torqued and the stop pins are compromised, the valve internals will not be damaged and the valve can still be opened and closed.

Product Information

-

The small-bore subsea ball valves are qualified at different pressure ratings up to 1,038bar (15,000psi) and are suitable for water depths to 3,050m (10,000ft). Qualification testing is performed to the exacting standard.

Product features

Operator – The ball valves can be supplied with a number of different operators, including Lever and Tee Bars, for diver operation.

Stop Pins – Each ball valve size has a stop pin designed for maximum torsional (Torque to Damage) strength.

Anti-Blowout Spindle – All ball valves have an anti-blowout safety feature.

Environmental Seals – All ball valves have seals to prevent the ingress of seawater. These have been tested to water depths equivalent to 10,000 feet (3050m).

Gland Seals – The gland seal within each ball valve is a Peek thrust ring with a secondary o-ring with a special anti-extrusion ring designed to prove a leak-free spindle sealing with no requirement for adjustment.

Ball – All Oliver Valvetek ballas are manufactured by its own production facility to ensure stringent Quality control and ball profiling design. The Oliver subsea ball valve range is high precision manufactured to extremely accurate sphericalness, which ensures extended operational life and is highly polished to provide minimum operational torques.

Seats – All ball valves utilise Peek seats which offer broad process compatibility whilst maintaining a positive sealing across the full pressure range from low to maximum working pressure.

Full Flow – Positive 90deg ball travel combined with clear through bore provides minimum restriction to flow.Traceability of Materials

All the components within an Oliver subsea ball valve have material traceability. The complete ball valves are individually serialised and are provided with material and pressure test certificates to BS EN 10204 3.1 certifications. Optional EN 10204 with the intent of a 3.2 type certification option is also readily available (EN 10204 3.2 true mill witnessed shall be assessed for availability upon request).BS EN 10204 3.1 as standard, 3.2 optional.

Product Enquiry

If you would like more information regarding our needle valves, please fill out the form below, or contact us directly on +44 (0) 1565 632 636 or sales@valves.co.uk.