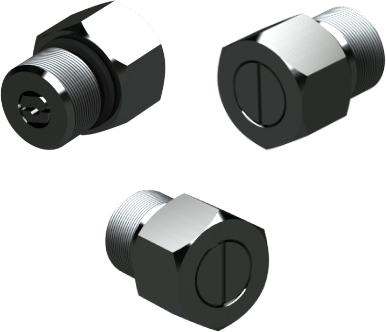

Subsea Rotary Gate Valves

Rotary Gate Valves

Oliver Valvetek offers a range of Rotary Gate Valves with nominal bore sizes of 3/8″ [9.5mm] and 1/2″ [13mm].

The small-bore subsea rotary valves are qualified at different pressure ratings of up to 15,000psi [1034 bar] and 16,500 PSI [1138 BAR] – 1.65 X CWP seat test was also conducted (if the system is rated at 10,000 psi). Rotary Gate Valves are suitable for water depths to 10,000 ft [3050m].

Qualification testing is performed to the exacting standards of API 6A Appendix F PR2 and 17D 2nd Ed (Operable temperature range: -20F [-29C] to +350F [+177C] with non-operable temperature range: -50F [-46C] to +350F [+177C].

The rotary valves offer a good alternative to a needle valve where typically you would expect to have low operational torques but high torques to damage. Another design feature is that should the rotary gate valve be over-torqued and extrenal valve stops are compromised, the valve will continue to rotate without damaging the internals.

Product Information

-

Small-bore Subsea Rotary Valves are used where metal to metal and non-elastomeric sealing is required on applications such as chemical injection lines on Christmas trees and manifold structures. In addition, a quarter-turn operation is required for position indication purposes.

<a href=”https://www.valves.co.uk/valvetek/”>Oliver Valvetek</a> provides a range of small-bore rotary subsea gate valves in bodies with flanged, threaded and welded end connections to suit all applications.

<strong>Key Rotary Gate Valve Features:</strong>Position Indication

The Oliver Valvetek manual rotary gate valves are operated through a quarter (90degrees) turn. This provides the end-user with a simple visual indication to the ROV operator of the valve position.Over-Torque Protection

The quarter-turn operation means that if the valve is over-torqued to a point where the end stops fail, the valve will simply continue to open and close. The valve can then be positioned in the open or closed position and without damage to the valve internals.Low Operating Torque

Oliver Valvetek has achieved a low operating torque at full differential pressure by utilising fine controls on the spindle to bonnet bearing interface.Panel Mountable or Block mountable

Oliver Valvetek can provide the end-user and operator with a varied and comprehensive range of operators and receptacles easily configurable to the designer ROV panel.U-shaped flow passage through the valve.

The unique design of the flow passage through the Oliver Valvetek rotary gate valve minimises the potential flow losses. Flow tested to provide the end-user with accurate flow coefficients and excellent Cv value if there is a concern regarding flow rates.Proven Destec Metal to Metal Body to Bonnet Sealing Arrangement.

Oliver Valvetek Rotary Gate valves utilise compact gaskets to offer effective and reliable body to bonnet metal sealing. Designed and tested to take total differential pressures from outside to in (10,000 ft hyperbaric conditions) and from inside of up to 18,750psi shell test conditions.Proven Sealing technology

Oliver Valvetek Rotary Gate Valves uses both static and dynamic sealing technology from other valves in it’s product range, thereby ensuring product reliability is maintained and utilising standardising sealing features across our product portfolio.For more information on Oliver Valvetek’s innovative Subsea Gate Valves, why not get in touch today?

Product Enquiry

If you would like more information regarding our needle valves, please fill out the form below, or contact us directly on +44 (0) 1565 632 636 or sales@valves.co.uk.