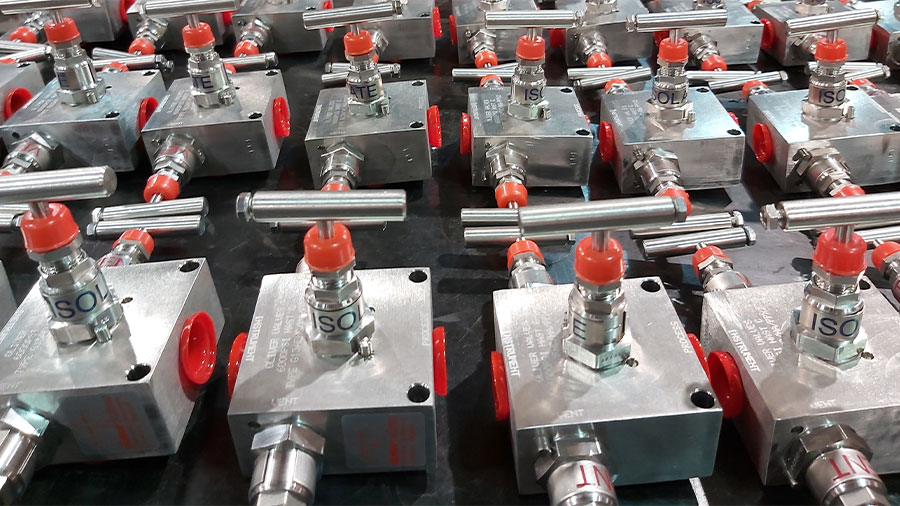

At Oliver Valves, we are an industry leader when it comes to Valve Manifolds and our team’s expertise and reputation for quality is unrivalled. Oliver’s Manifolds are used in many fluid power applications. According to the usage of the manifold valves, it comes with various kinds of configurations.

A manifold, however, is a device that connects one or more blocks or isolates valves in any form of the system; this can include a ball or needle valve. From Isolating Instruments, controlling high-pressure fluid flow to regulating the pressure, manifold valves perform a variety of functions.

In the case of a block and bleed manifold, the purpose is to safely isolate and remove an instrument from its application. Oliver’s design guarantees secure isolation via the Non-Rotating Tip Needle Valve. As a secondary action the operator vents the excess media that remains in the cavity, between the instrument and manifold. Once these steps are complete the end-user can safely remove the instrument for calibration.

Manifolds are instruments that come in various forms, single isolates, block & bleed or block, equalise bleed, which can be connected to a transmitter directly or via a remote mount method. Valve Manifolds are mostly made of stainless steel, carbon steel, or alloys; they help measure static, variable, gauge, and differential pressures.

Manifolds are widely used in sectors such as oil, gas, chemicals, wastewater, power, and so on. At Oliver Valves, we offer a variety of precision-engineered valves and valve Manifolds to meet most flow, pressure and level measurement application requirements.

Advantages of a manifold valve

Manifold valves are used in a number of different applications, ranging from mobile machinery to heavy industrial equipment. At Oliver Valves, our customers have benefitted from Needle Valve Manifolds being supplied with mounting bolts and seal rings.

So, what are the advantages of incorporating valve manifolds into your process piping system?

- Valve manifolds afford more efficient system operations in comparison to opening and closing each valve independently.

- Since they operate more efficiently, valve manifolds reduce plant energy consumption and associated costs

- Due to increased efficiency, they reduce downtime when cleaning process lines

- Increased safety from guaranteed isolation from dangerous medias

When properly designed and laid out, valve manifolds:

- Allow for shorter fluid paths and smaller footprints, reducing the likelihood of pressure drops and heat fluctuations.

- Require fewer connections between pipes, lowering chances of leaks

- Reduce installation costs due to the more straightforward and more compact layout they afford

Oliver Valves works extensively with many clients in customising designs and configured them to meet the system’s specific requirements. If you would like more information about the valve manifolds we supply, please contact Oliver Valves today