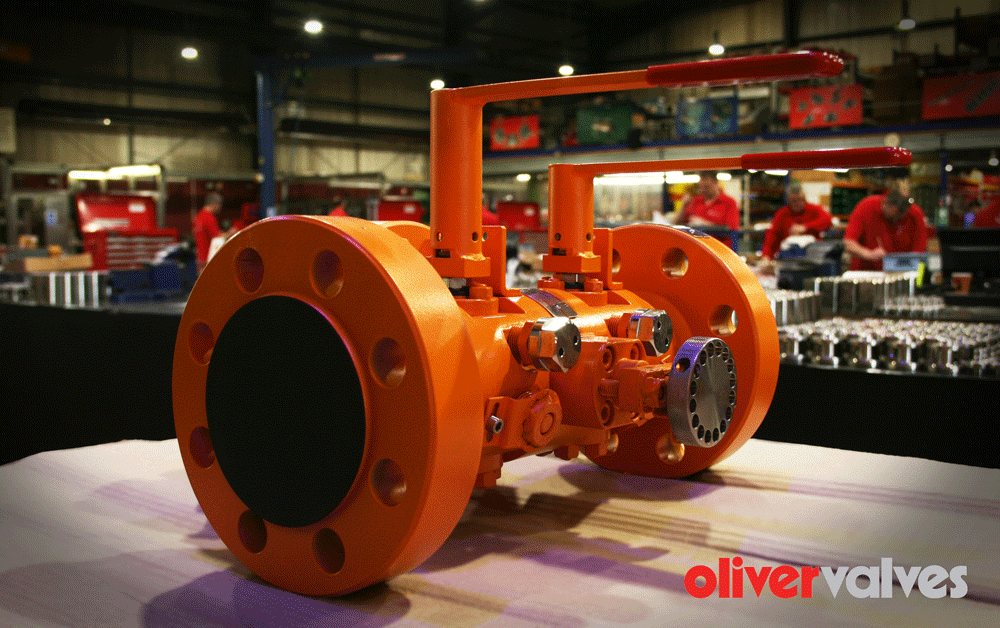

Oliver Twinsafe Trunnion Mounted valves and Floating Ball Valves have successfully been SIL certified at level 3. This new and important milestone provides operators with safety assurances at the highest level and has resulted from many months of engineering design, QA reviews, and audits.

A SIL (Safety Integrity Level) is a measure of safety system performance, in terms of probability of failure on demand (PFD). The higher the SIL level, the higher the associated safety level, and the lower probability that a system will fail to perform properly. SIL 3 is the highest rating that can be given to a valve.

High Integrity Pressure Protection Systems (HIPPS) and remotely located well-head manifolds are normally associated with SIL certification. Operators are to gain additional safety assurances from installing our ball valves, in that, when the valve is required to perform its fail-safe function, the probability of it not performing is extremely low.

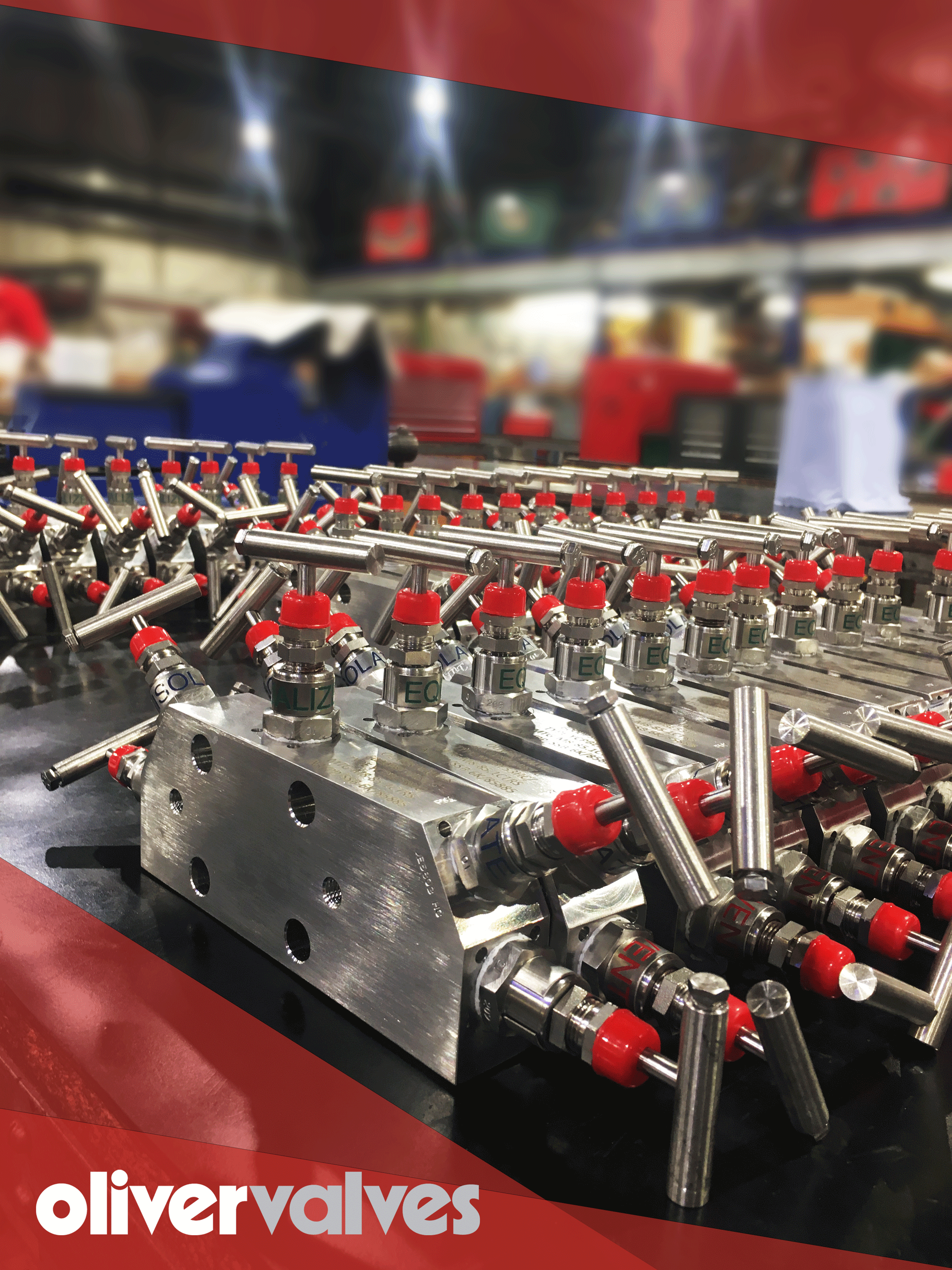

SIL 3 certification has been awarded by Exida, a third-party safety assessment organisation. The certification covers our range of Single Isolate valves, and Double Block and Bleed valves comprising two separate isolates within the assembly. Bore sizes for Trunnion Mounted valves range from 1” – 16” and 1” – 3” on Floating Ball valves.