There are countless types of valves for use across a variety of industries and applications. One type of valve that is commonly used is a Needle Valve. Oliver’s unique & innovative design allows the customer to Isolate or control the flow rates of gasses or fluids accurately. The adjustments are gradually made to control the flow rate smoothly and designed in a way that makes the operation easy, guaranteeing zero leakage and above all offering safety to all of our customers.

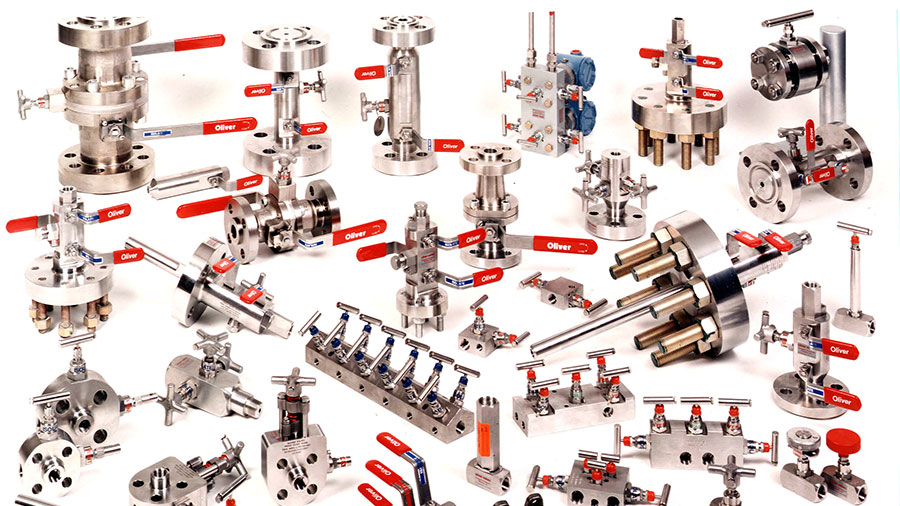

Established 40 years ago, Oliver Valves is one of the world’s leading manufacturers of instrumentation Needle Valves.

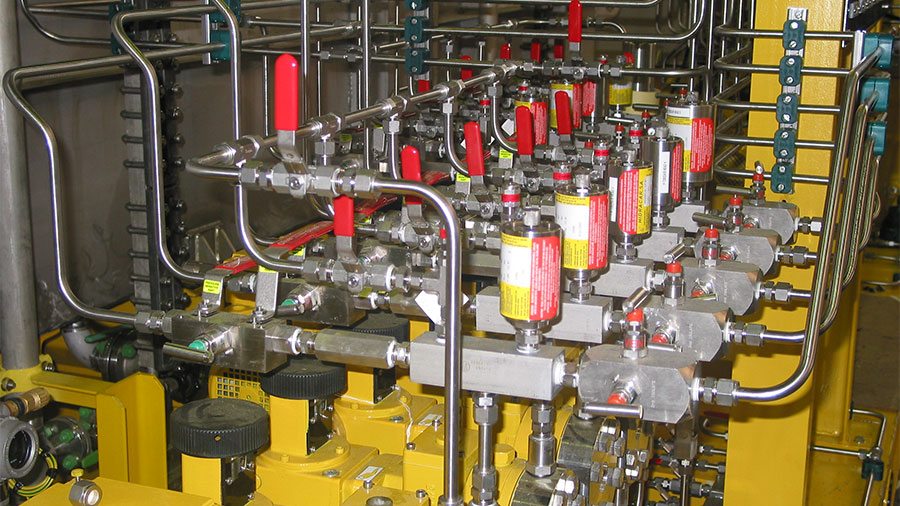

With an unrivalled level of quality and support, from implementing valve solutions directly into existing projects to pioneering new technology, we offer a diverse range of Instrumentation Valves for the Global Oil, Gas and Petrochemical Industries.

Like most valves, Needle Valves are responsible for the safe and efficient operation of industrial machinery, flow measurement and control applications, but how does a needle valve work?

How Does a Needle Valve Work?

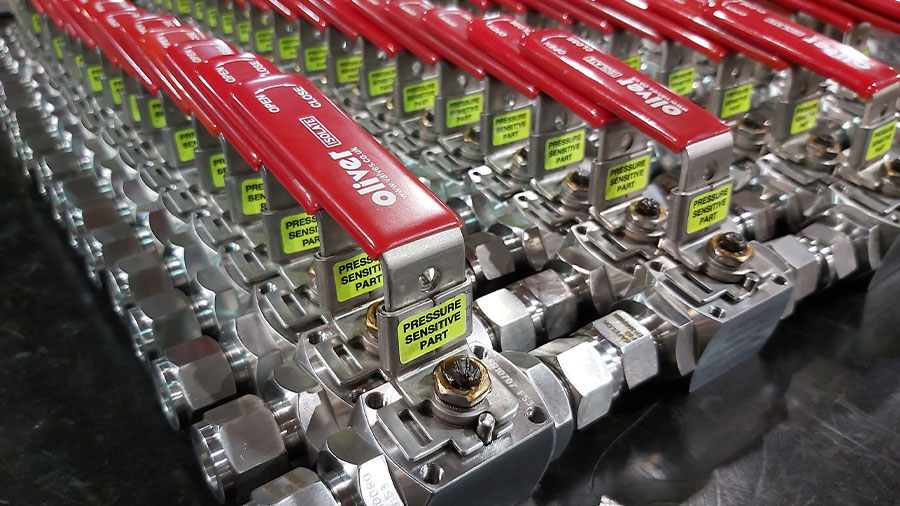

Needle Valves are operated manually and utilise a Tee Bar or Handwheel to control the distance between Oliver’s unique non-rotating tip and the valve seat. When the valve is turned in one direction, the tip is lifted to open the valve and allow fluid to pass through. When the valve is turned in the other direction, the tip moves closer to the seat to decrease the flow rate or close the valve.

Manually operated Needle Valves provide zero leakage isolation and precise control of the flow rate. As a result, a Needle Valve can help you better isolate or regulate the flow rate of fluid in the system.

Needle Valve Uses

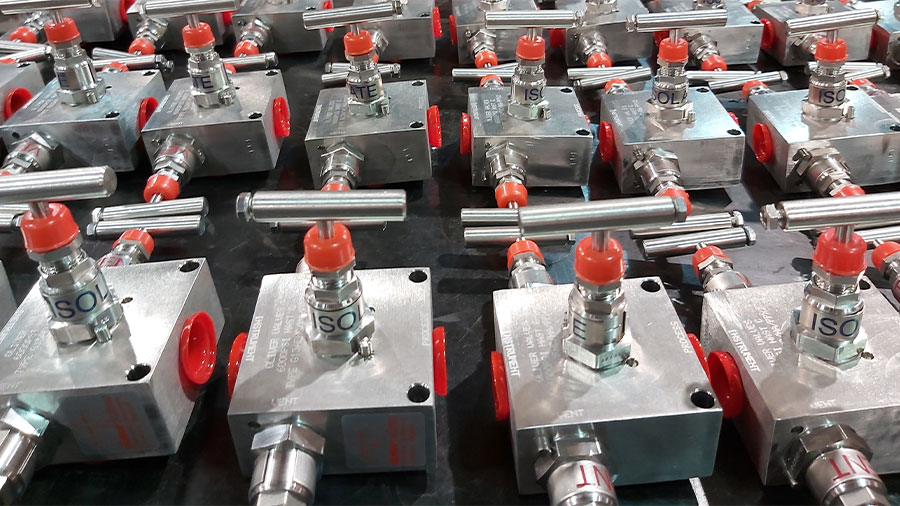

At Oliver Valves, our Needle Valves are produced to the highest machining standards, utilising fully traceable materials to provide metal-to-metal seating with zero leakage. Our unique design of tip eliminates potential wear, extending the life expectancy, whilst our anti-blow-out spindle design guarantees safety throughout your application and plant. They are suitable for many applications without resorting to larger and more expensive globe valves. Needle valves are often used in power plants, refineries, chemical plants, oil and gas exploration, laboratory analysis, low-pressure hydraulic systems, chemical processing, and other gas and liquid services, etc.

Needle valves are commonly used to Isolate or control flow and protect delicate gauges from damage caused by sudden pressure surges of liquids and gases. They’re ideal for systems using lighter and less viscous materials with low flow rates; they can also be applied to high-temperature and oxygen services based on their materials. Needle valves are often made of stainless steel, bronze, brass, or metal alloys; when choosing a needle valve, you should ensure that it is made with the material that’s best suited for the service you need. Considering the efficiency and the durability of a valve is essential, primarily because of a valve’s extensive use within many industries.

At Oliver Valves, our team can assist and advise you on which valve to use and help to preserve that valve’s service life to keep your systems running smoothly and safely. If you would like more information, please contact us today.