Oliver Valves has secured a fixed 3-year contract to supply a large range of valves to the Kaybob Duvernay project in North America.

Located in Fox Creek, Alberta, Canada – Kaybob covers an area of 330,000 acres, equivalent to 4/5 times the size of London and is estimated to produce 22,000 barrels of natural gas per day.

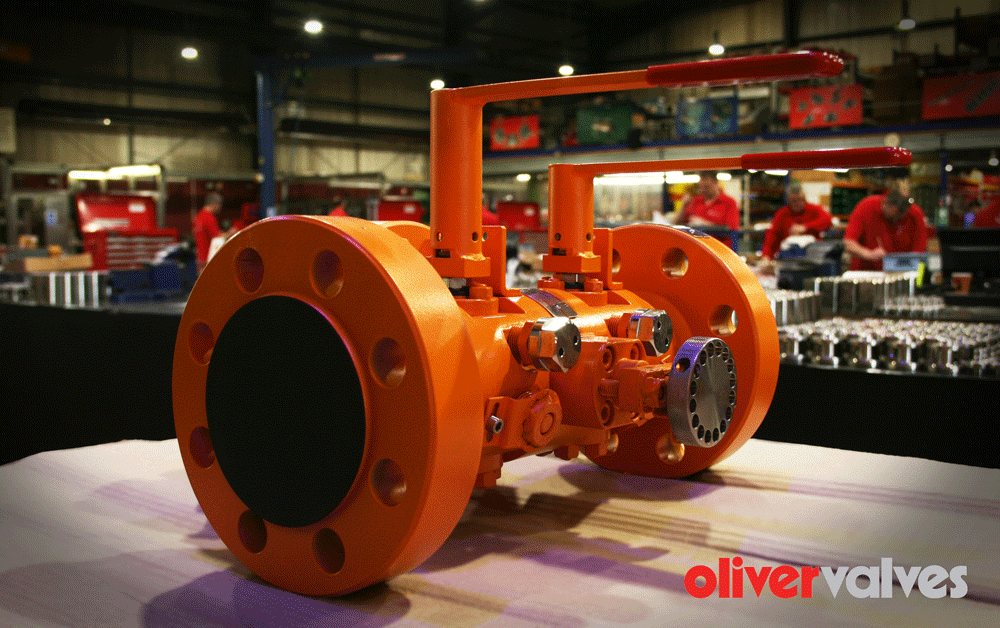

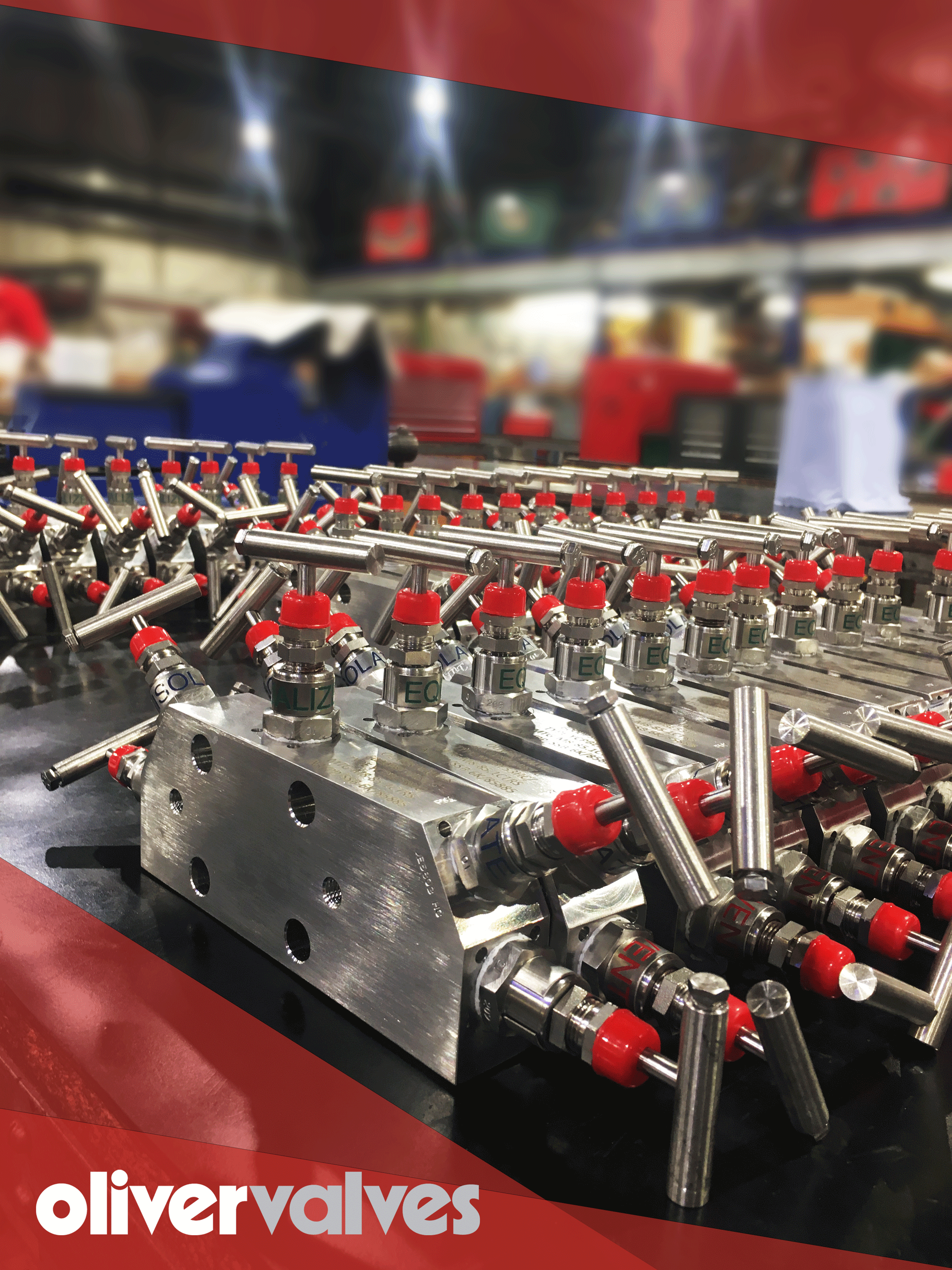

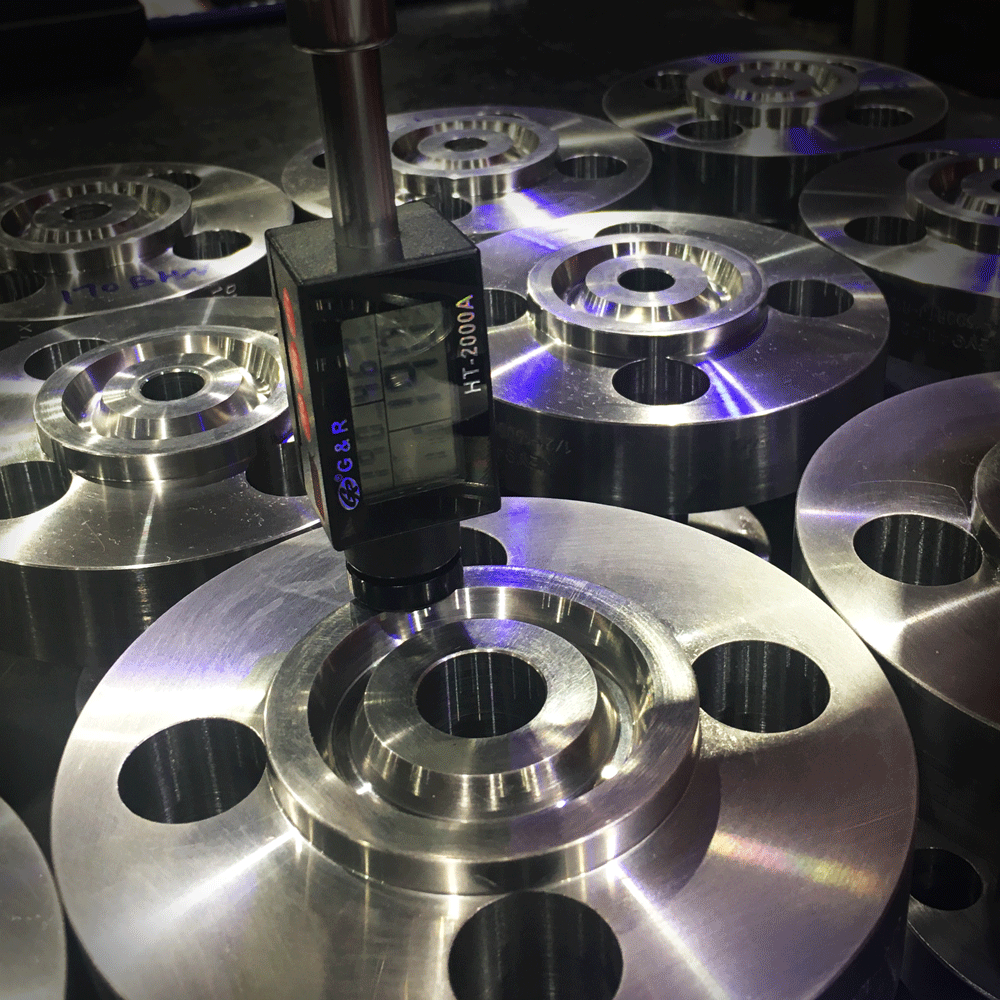

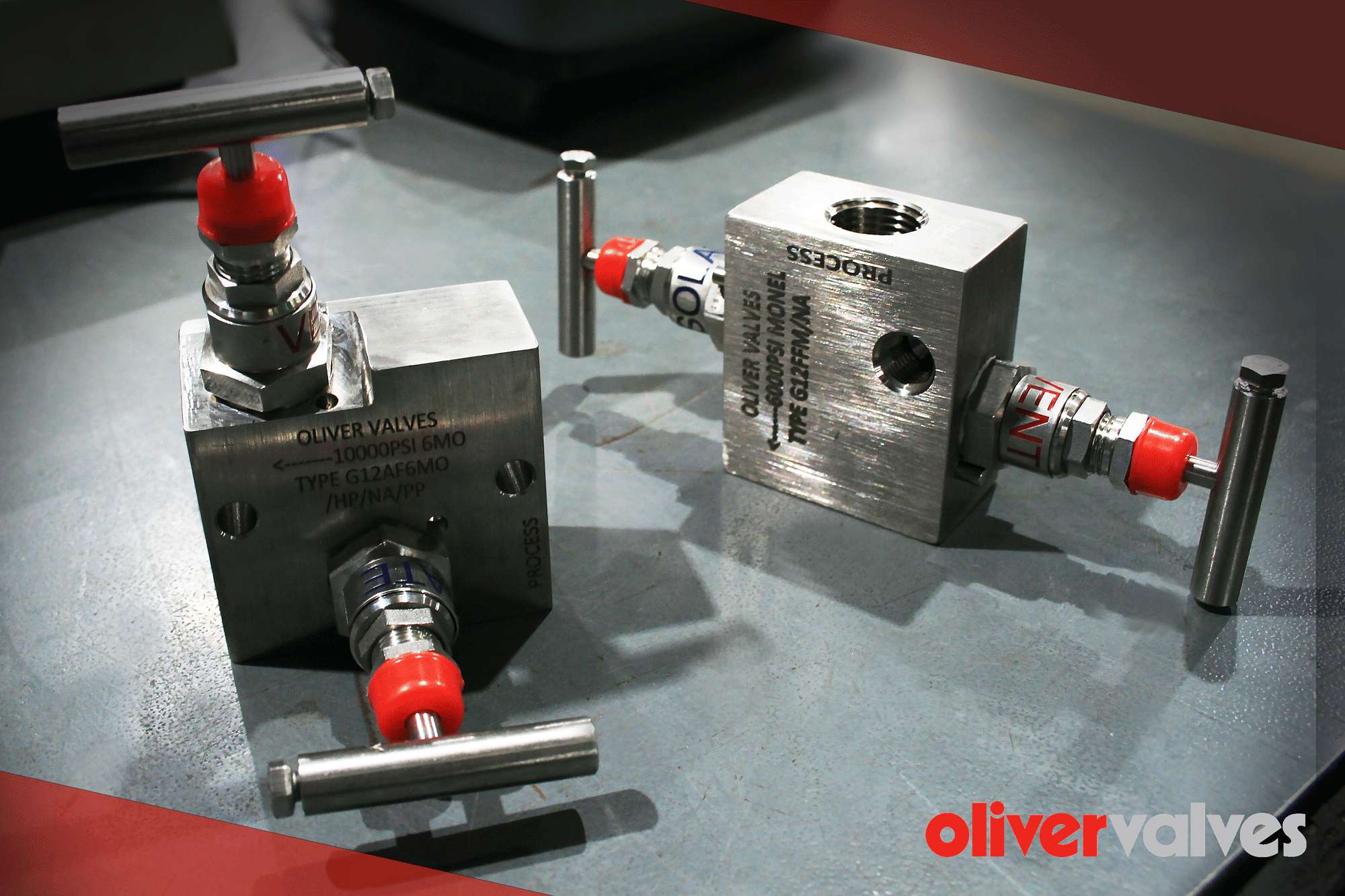

Almost half-way into the contract, Oliver has supplied a significant number of Instrument Manifolds and Reduced and Full-Bore Double Block & Bleed valves from our sister company Twinsafe, with injection and sampling probes, in orders placed so far worth over £500,000. Oliver engineers carried out strength calculations that were needed to gain approval and to obtain Canadian Registration Numbers (CRN), which is a legal requirement for pressure rated products to be installed and operational in Canada.

An exciting project for Oliver’s to be a part of explains Martin Orme, Key Account Sales Engineer. “We have worked with distributors and energy contractors in the U.S and North America for such a long time that our experience of designing and developing valves for specific applications with clients is largely the reasons why Oliver’s are selected for major projects such as this.”

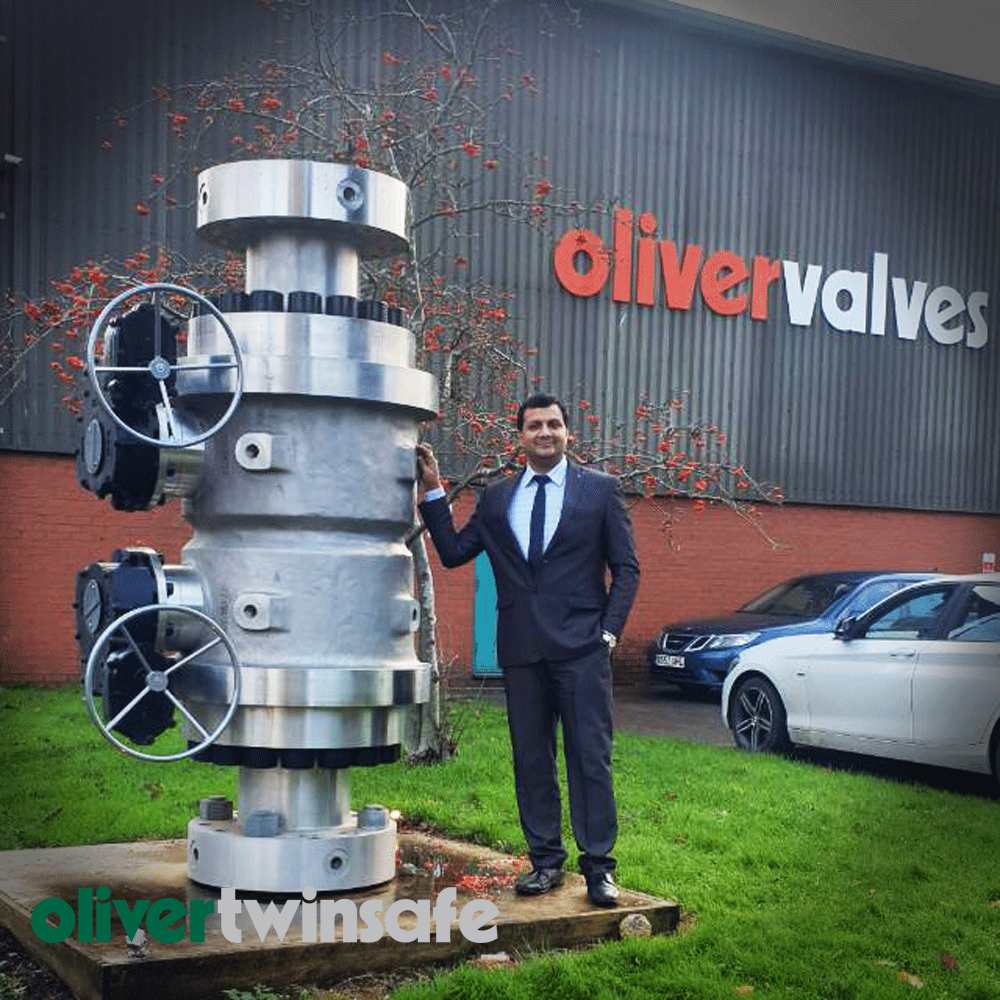

Valve safety, performance and manufacturing quality are the cornerstones of Oliver’s success and their strong customer relationships are what set them apart from other suppliers. Another unique strength is their dedicated Research & Development facility in Knutsford, England.

Martin continues, “Obtaining relevant documentation and registrations like CRNs can be an arduous task, but by having a dedicated research, development and testing centre, we’re able to meet the most stringent of end-user specifications such as we have done on this scope of work.”

Oliver Valves and its sister company Twinsafe, who specialise in pipeline valves, work with clients around the globe on oil, gas and hydrogen projects to provide world-class valve solutions that include Zero-rate A valves for hydrogen applications. Visit their website for more details at: www.valves.co.uk.