Orders have started to roll off the production line for Oliver’s NEW Hydrogen double block & bleed and ball valves. After months of Research & Development and meticulous testing at our purpose-built R&D facilities in the UK, the ball valve was passed and certified for Hydrogen application by Third Party Inspectors in July of this year.

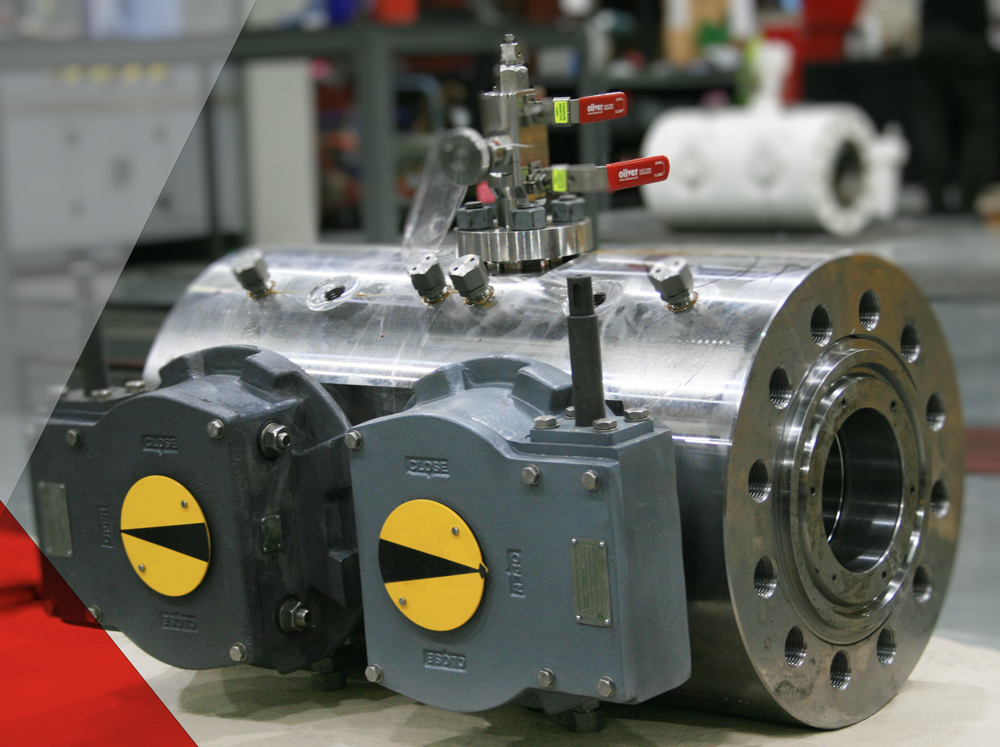

Various DBB and single isolate ball valves with 14mm Bore Flange to Flange have gone into full production having taken another order, this time from Rockfin. Valves pictured here can be seen undergoing pressure testing on our recently installed state-of-the-art test rigs, and are scheduled for immediate dispatch to Poland

The valves meet with stringent ISO 15848-1:2015 Tightness class B certification including ISO 5208:2015 zero seat leakage rate A. This has been achieved with precision engineering and providing a high-quality seal face finish.

For more information on Oliver Hydcovalves range of hydrogen valves or to discover more about Oliver R&D capabilities, please contact Nick Howard or Rob Porter on 01565 654 089 or email: sales@valves.co.uk | www.valves.co.uk