Rockfin are a world-leading engineering company specializing in the design, manufacture, testing and servicing of oil and fuel systems for gas turbines, steam turbines, generators, compressors and high-pressure drives and control systems. Working very closely with MAN Energy Solutions Schweiz AG, Rockfin recently secured an order to supply two skid packages to the Lysekil Refinery in Sweden.

Rockfin already had close relationships with Oliver Valves from previous projects, but with the application demanding products suitable for use with hydrogen as the process media, the enquiry was quickly diverted to Oliver Hydcovalves; the latest addition to the Oliver family of companies dedicated to new energy applications.

We were able to present Oliver Hydcovalves to the Rockfin team, exploring the technical challenges driven by hydrogen valves applications and showing how we have developed valve technology specifically to meet these challenges head on.

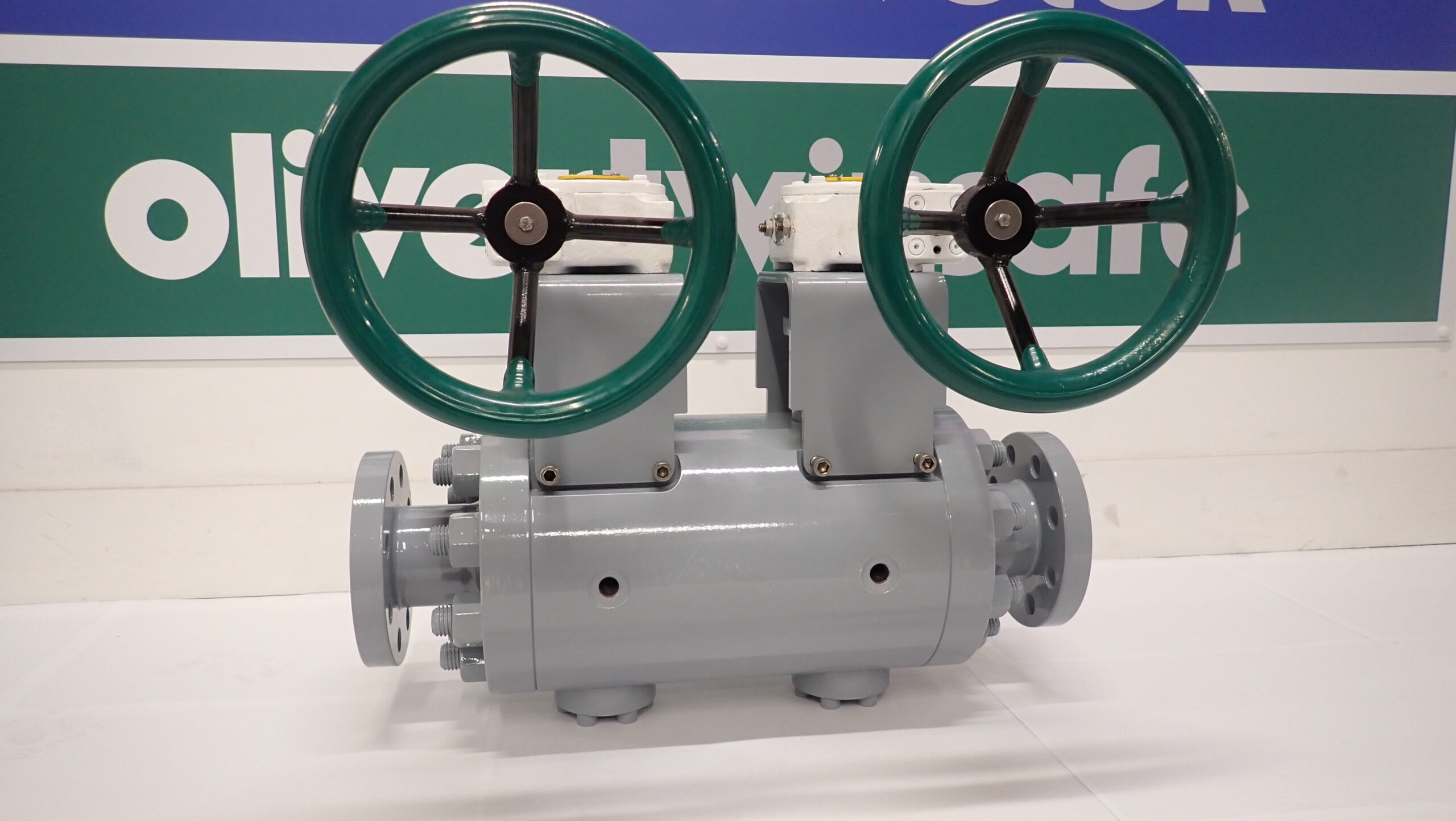

Rockfin’s confidence in our new brand and knowledge of hydrogen valve technology convinced them to place a significant order for a number of isolation manifold block valves in both DB and DBB configuration.

Rob Porter, Area Sales Manager for Oliver Hydcovalves states, “Once we were engaged with the team at Rockfin, we quickly worked through their requirements and matched our hydrogen compatible products to their specific needs. We are really excited by the opportunity to work with a highly professional and technically capable company like Rockfin on sustainable energy projects such as this.”

These valves will utilise fully hydrogen compatible materials, including the latest polymer seal technology design specifically to meet the demands of hydrogen applications. Both stem and seat seal arrangements have been tested at Oliver’s in-house R&D facility to ensure long service life, reliability and safety.

Oliver Hydcovalves continues to develop valve technology for the emerging hydrogen energy sector, including valves for hydrogen production, storage and transportation. We are dedicated to supporting customers that strive to deliver a more sustainable future, helping them meet their net zero ambitions.

For further information contact Rob Porter at rporter@valves.co.uk or simply call us on +44 (0)1565 632636. Or visit us at https://www.valves.co.uk/hydcovalves/