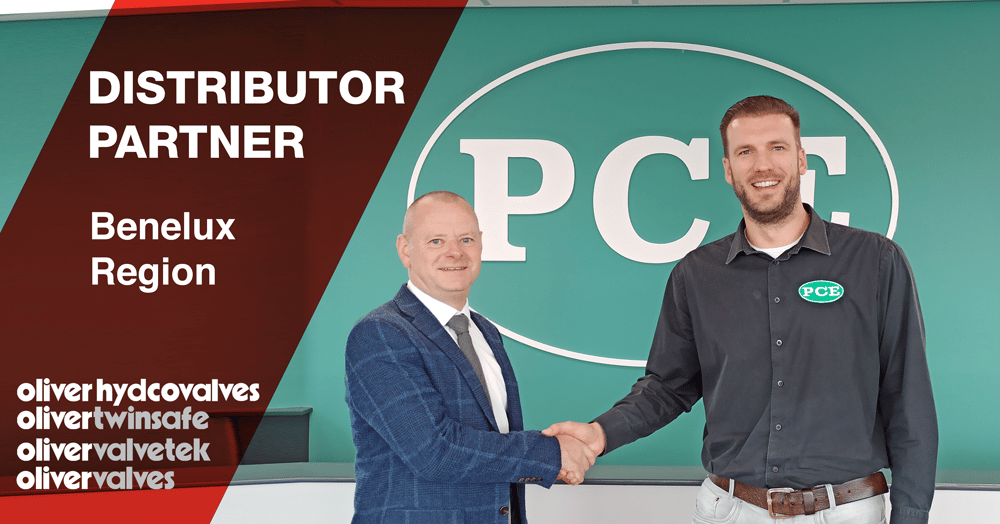

We’re very excited to announce that Process Control Equipment Ltd Netherlands, is our new distribution partner for the Benelux Region of Europe for Oliver Valves, Oliver Twinsafe, and Oliver Hydcovalves.

Strategically located for distribution, in the town of Ridderkerk, close to Rotterdam, PCE operates from 10,000 sq/ft purpose-built warehousing facilities, where they’ll house dedicated stock holding of the Oliver valve range. PCE also has a sales office near Antwerp, perfectly placed to service and support the Belgian market.

Oliver Valves and PCE, two family-owned businesses, have been working together in the UK for more than 20 years, forming a very close relationship in that time. We’re really excited to be taking our successful partnership to the Benelux region and are confident that we’ll continue and strengthen our ongoing support to existing customers and welcome new ones.

Pictured is Andy Hole, Oliver Valves Territory Manager for Europe and Africa with PCE Benelux General Manager, Arno van Bekkum.

For valve sales and enquiries contact:

PCE Benelux, Schillingstraat 17, 2988 Ridderkerk, Netherlands

sales@pce-bv.nl

www.pce-bv.nl

Oliver Valves – Andy Hole, Sales Manager (Projects & Distribution)

ahole@valves.co.uk

www.valves.co.uk