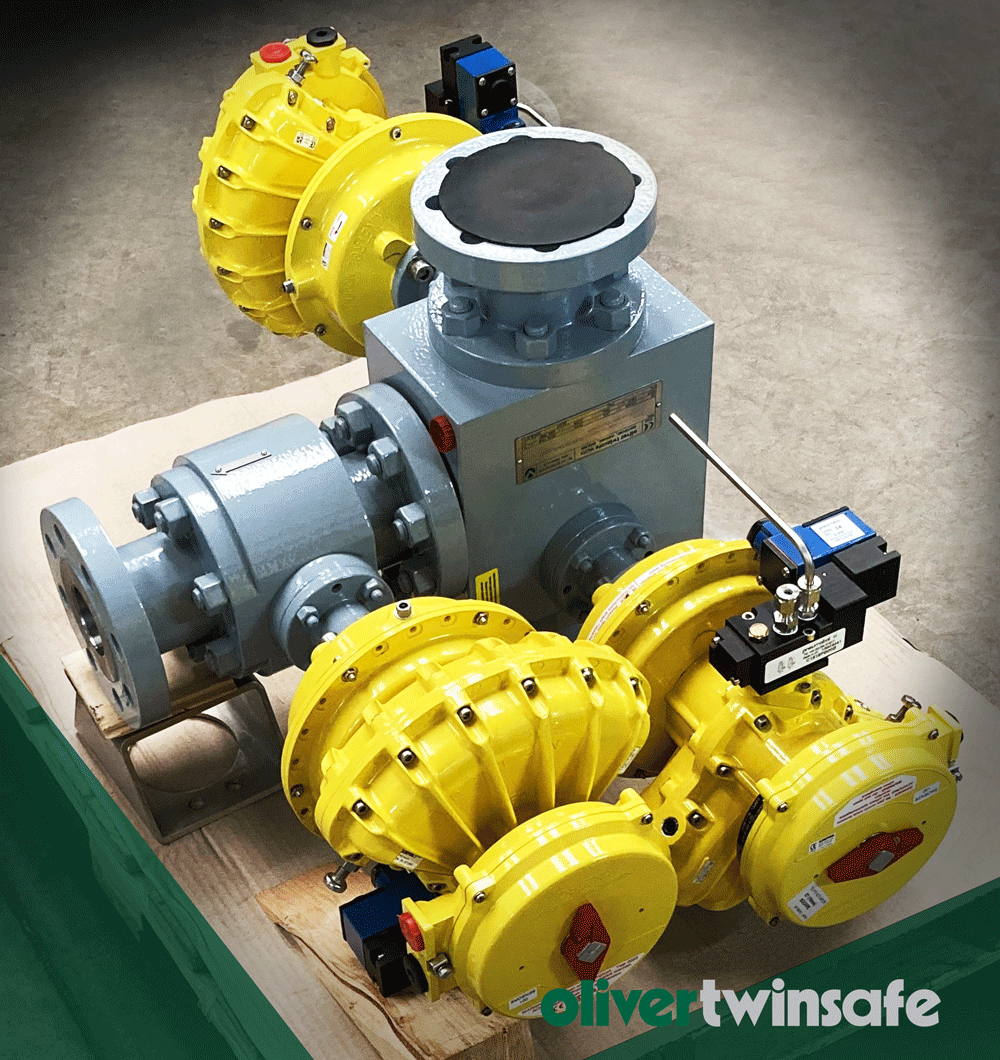

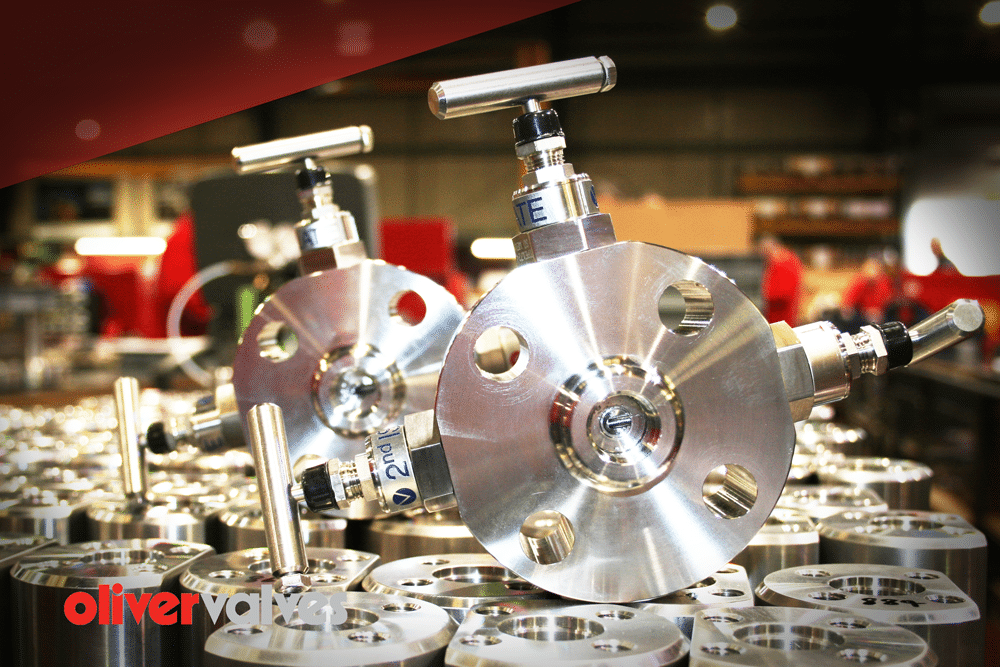

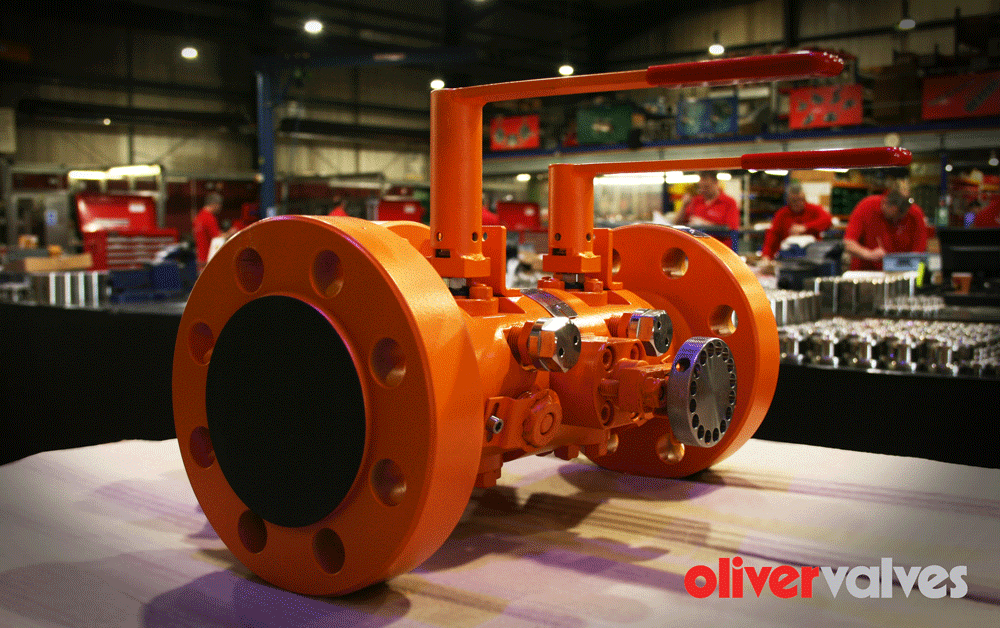

Oliver Valves has appointed Process Control and Equipment (PCE) as an authorised distributor for their instrumentation, Double Block and Bleed, Pipeline, and Hydrogen valves in Spain and Portugal.

As the preferred distributor for the UK, this strong partnership with PCE has been built over 20 years. The announcement follows PCE’s appointment for the Benelux region in 2022, and falls in-line with Oliver’s European strategy to deliver high quality valve solutions ‘nationally’, with efficient after-sales support ‘locally’. PCE is integral to delivering on this.

Oliver Valves territory manager for Europe and Africa, Andy Hole, said “Our unrivalled reputation for valve solutions has been strengthened further with professional representation of our brands in the Benelux region, and we’re very excited to continue the success with PCE in Iberia.”

Having successfully delivered product and after-sales support training to PCE this month, the key learning outcomes were mutually beneficial – with discussions around market opportunity, and how well we can support each other in achieving our goals.”

For more information on how Oliver Valves and Oliver Twinsafe can supply your project with the very best valve solutions, contact us on +44 (0)1565 632 636 or email sales@valves.co.uk | www.valves.co.uk