Oliver Twinsafe win order to manufacture a large number of 2” API 6D, Class 900 Double Block and Bleed pipeline valves for operation on the Dammam Redevelopment in Saudi Arabia. The project is a typical oil development located onshore.

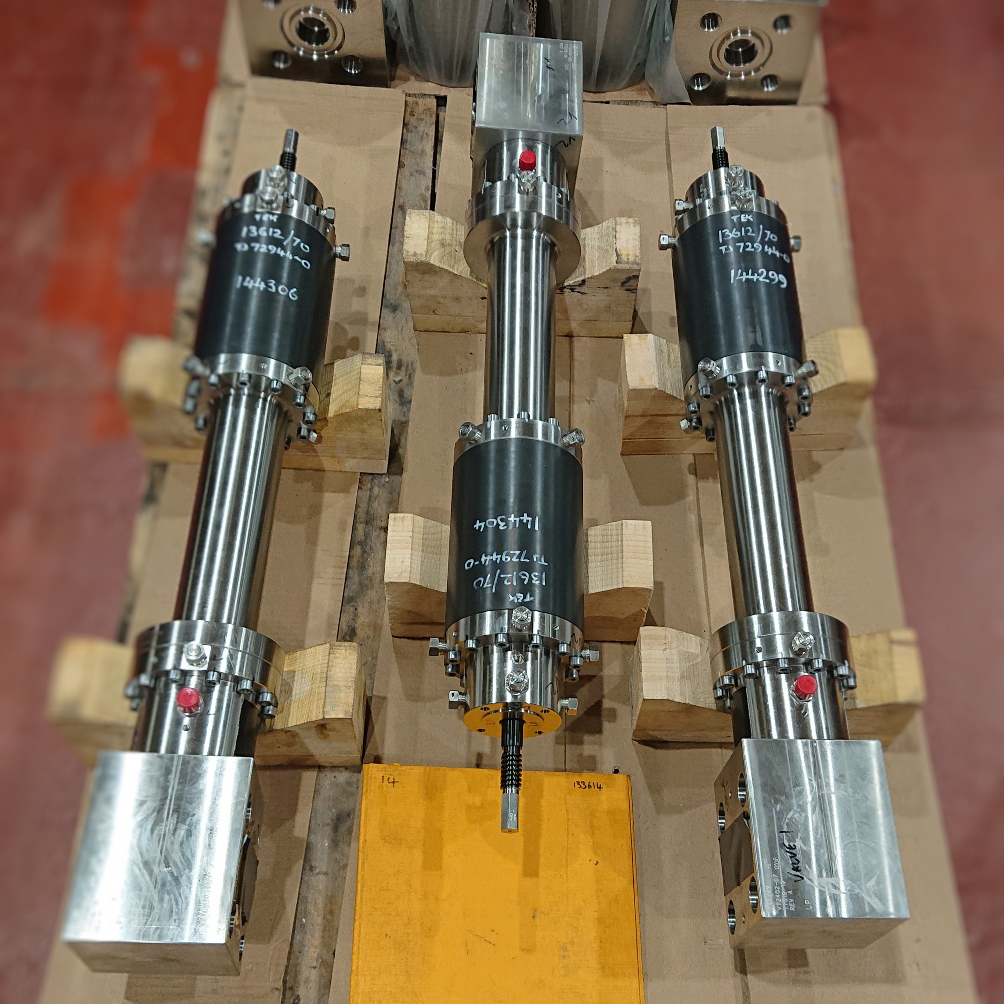

DBB valve specifications include internal 625 weld overlay on all wetted areas. Currently, valves are in testing and will shortly reach production stage, before being shipped directly to sites A and B of the Dammam drill site.

The order is testament to the high standards of valve safety and performance of Oliver Twinsafe pipeline valves operating on energy production projects around the globe.

For more information on pipeline valves, contact Oliver Twinsafe on +44 (0)1565 632 636 or email sales@valves.co.uk | www.valves.co.uk