Ball Valves

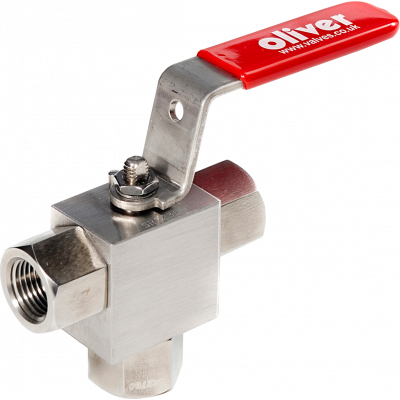

B10M Ball Valve

The ‘B10’ Type Single Isolating Ball Valve is designed for safe and reliable isolation giving bubble tight shut off. The totally enclosed soft seats offer positive sealing and low operating torques, from vacuum to high-pressure service.

Fitted with an anti-blow out spindle as standard, the B10M Ball Valve comes with the option of PTFE or Grafoil seals.

Product Information

-

The ‘B10’ Type Single Isolating Ball Valve is designed for safe and reliable isolation giving bubble tight shut off. The totally enclosed soft seats offer positive sealing and low operating torques, from vacuum to high-pressure service. Fitted with an anti-blow out spindle as standard, the B10M Ball Valve comes with the option of PTFE or Grafoil seals.

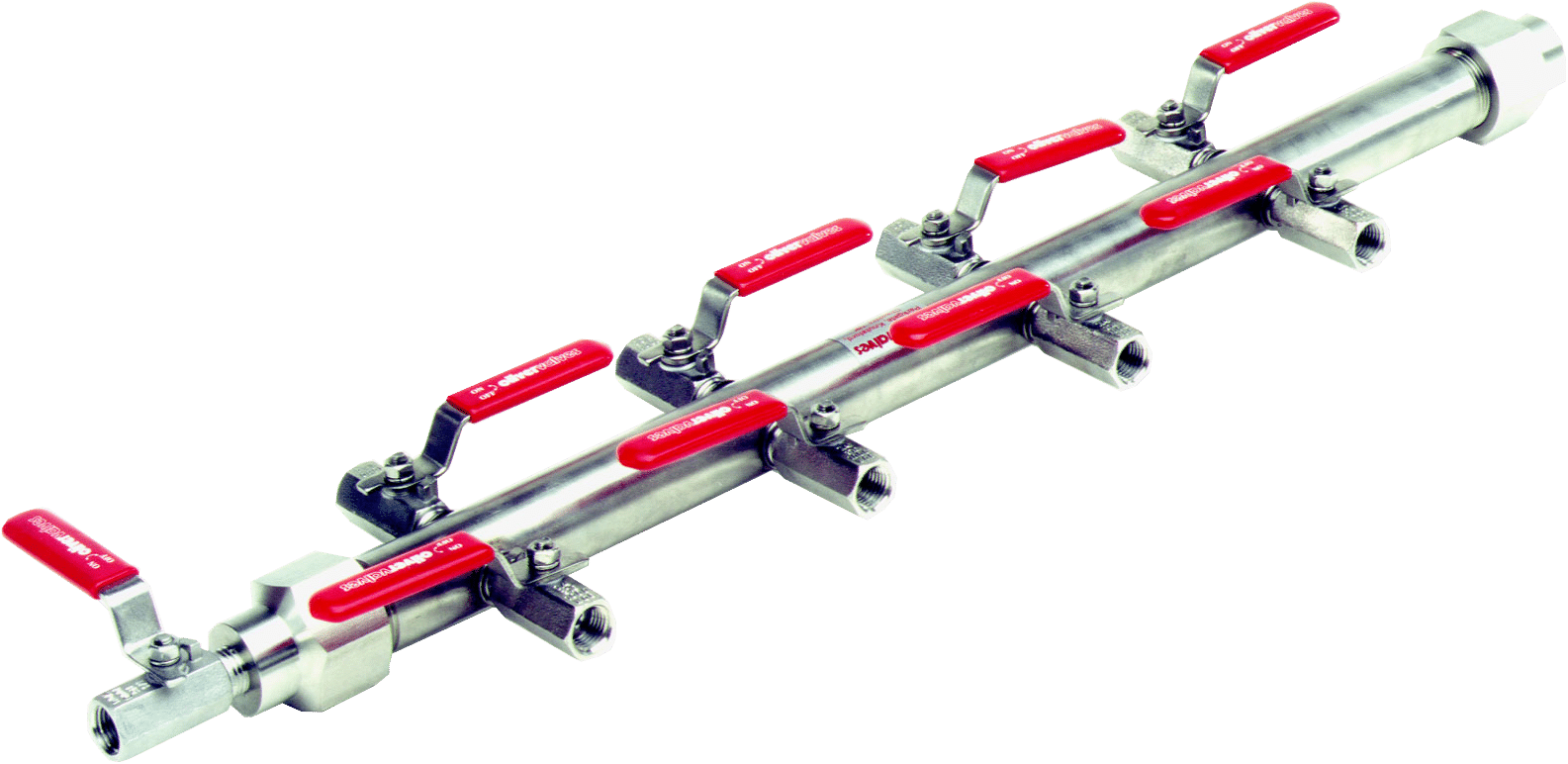

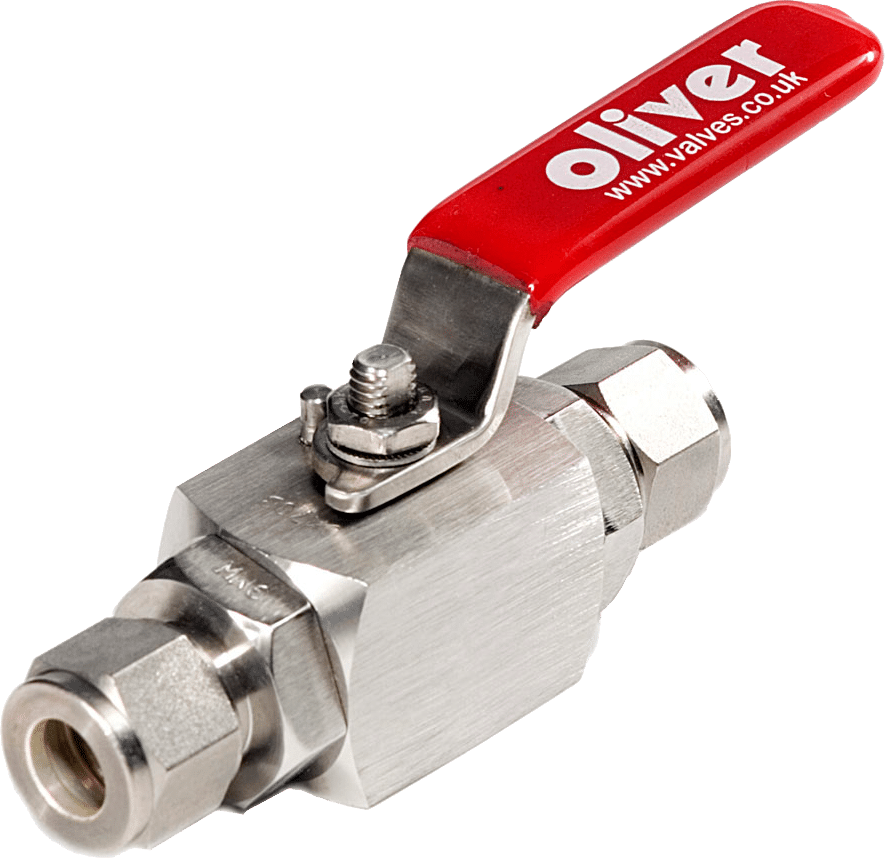

The B10M High-Pressure Ball Valve is available in three different configurations, namely: Integral Compression Ends, Threaded Ends Female x Female and Threaded Ends Male x Female.

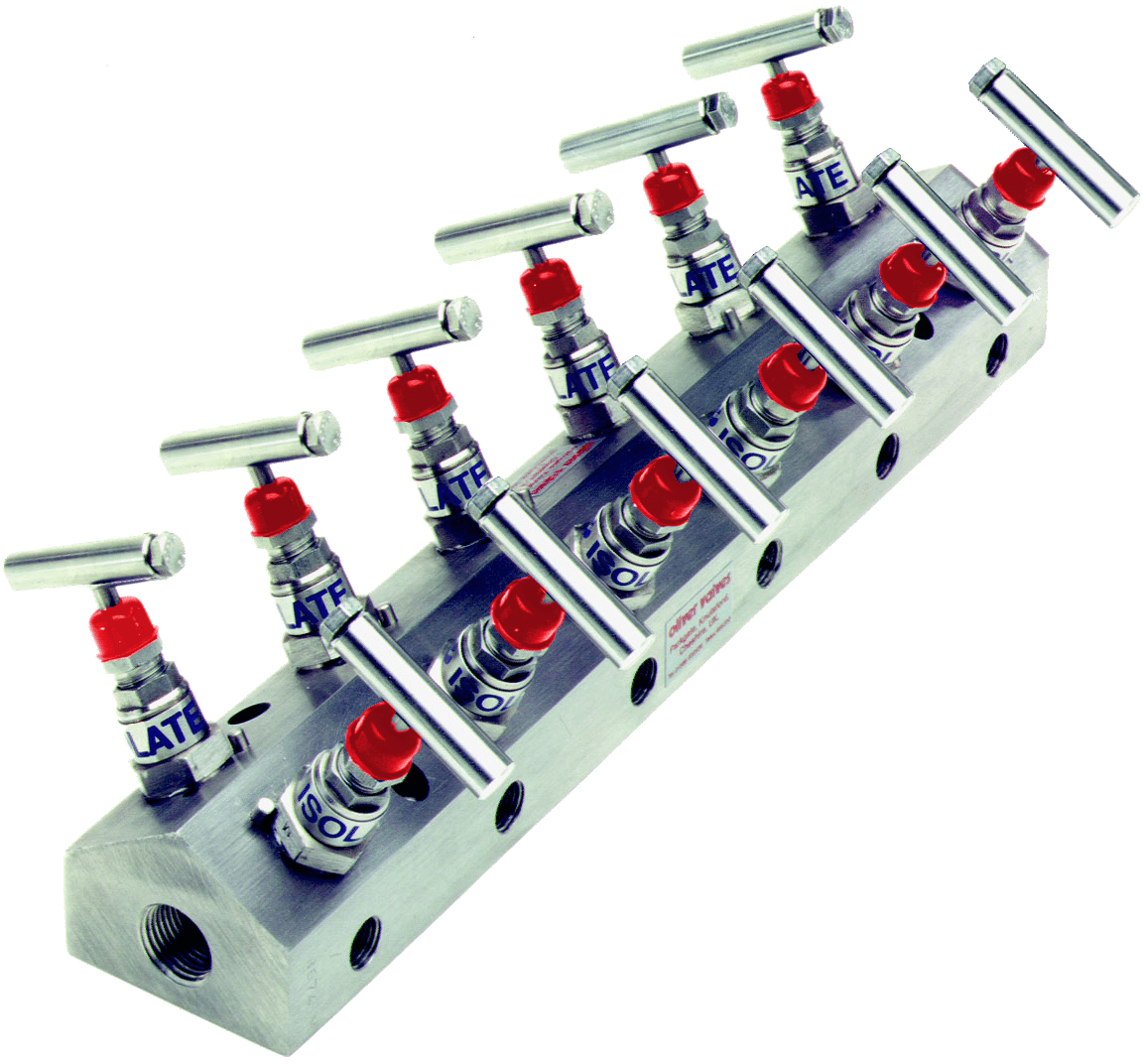

As with our low-pressure ball valves, our High-Pressure Ball Valves offer totally enclosed soft seating, which gives the valve a positive sealing and low operating torques across the whole pressure range. Contrary to our low-pressure ball valves, our High-Pressure Ball Valves are capable of withstanding PSI ratings up to 10,000 PSI; they are also recommended for use within the Oil, Gas and Petrochemical industries.

With a one-piece spindle with an anti-blow shoulder, our High-Pressure Ball Valves maintain seal integrity throughout the pressure ranges. We are also able to work with customers to provide High-Pressure Ball Valves with increased body integrity through either PTFE or Graphite Foil spindle and body seals.

The handle found on our High-Pressure Ball Valves is manufactured using 316 stainless steel, fitting with twin anti-vibration locknuts.

3D Models are available upon request

Available as Firesafe to BS6755 Pt2

NACE MR-01-75

Our team offers a diverse range of ball valves for the global Oil, Gas and Petrochemical industries. For more information, please get in touch with the team at Oliver Valves.

Product Enquiry

If you would like more information regarding our needle valves, please fill out the form below, or contact us directly on +44 (0) 1565 632 636 or sales@valves.co.uk.