DBB Pipeline Ball Valves

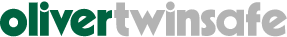

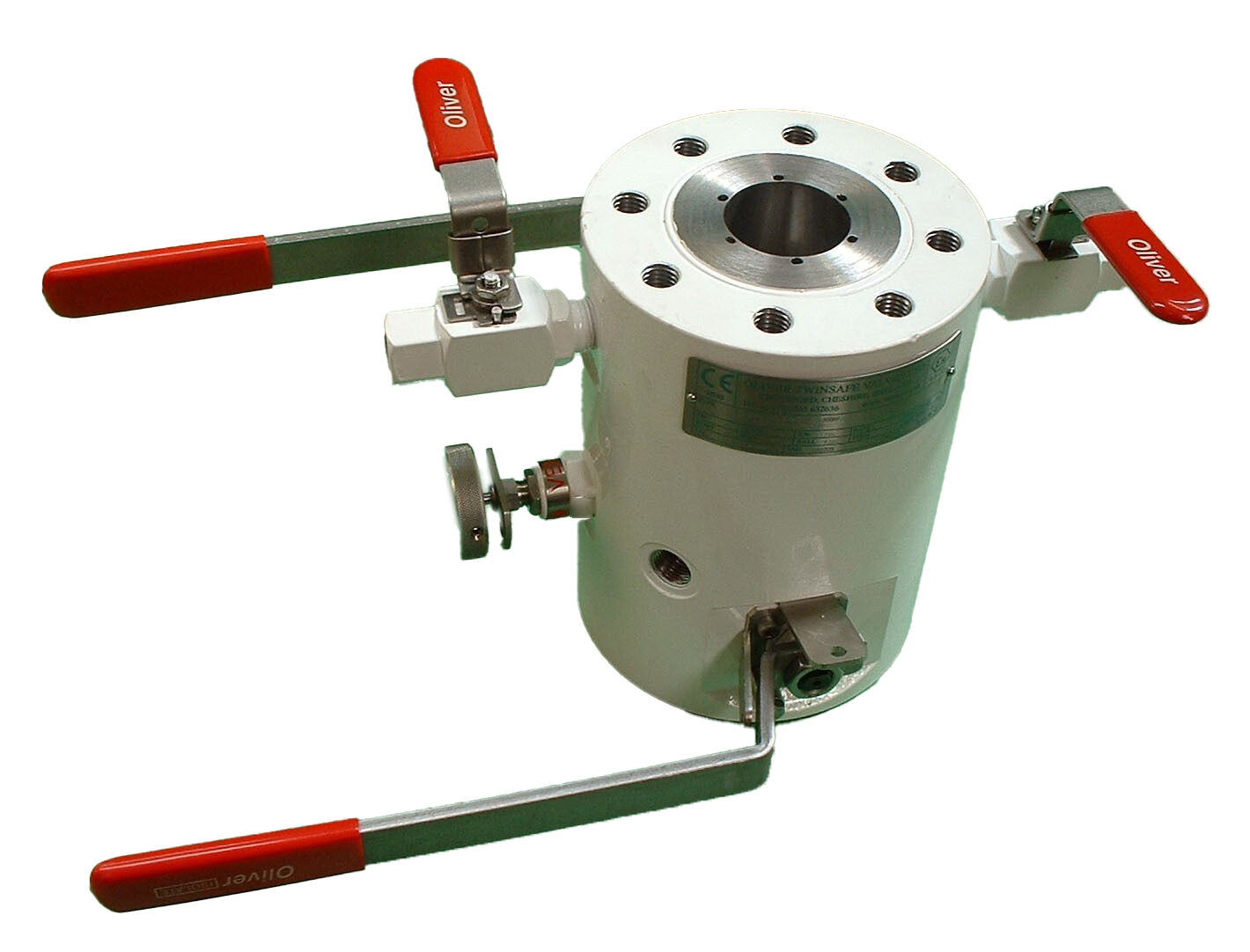

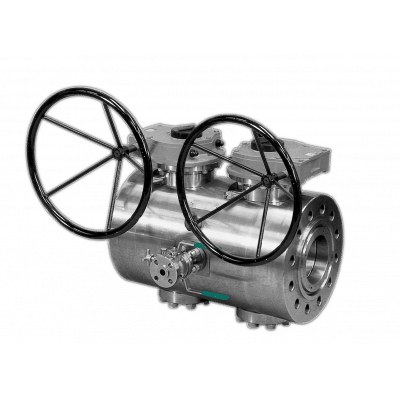

Trunnion Ball Valve DBB Flanged 3 Piece Design

Our Flanged Style Double Block & Bleed Valves are designed with a bolted 3 piece body and conventional through bolting flanged connections. The design reduces potential leak paths and allows weight and space savings when compared to conventional piping methods. Available in both full and reduced bore sizes.

Product Information

-

The 3 piece bolted construction provides conventional through bolting of the flanged end connections, plus the option of hub or welded ends. The overall lengths of the valve are kept to a minimum and offer considerable cost, weight and space savings over conventional piping methods of double block and bleed, using separate ball valves and spool pieces.

Valves are available with full bore sizes in accordance with API 6D, ensuring maximum flow for increased production rates and allowing pigging of the pipe line.

The integral trunnion plate design reduces leak paths through the body.

Various bleed valve options and connections are available in line with customer requirementsAvailable up to 16″ full bore (larger sizes on request).

Trunnion mounted design from 2″ to 16″.

Flanged connections in accordance with ASME B16.5 or API 6A, hub connectors or welded ends also available.

Integral vent valve with both threaded and flanged connections available.

Product Enquiry

If you would like more information regarding our needle valves, please fill out the form below, or contact us directly on +44 (0) 1565 632 636 or sales@valves.co.uk.